-

JDB محمل التشعبات الصلبة جلبة محمل شفة الجرافيت ذاتية التشحيم والخالية من الزيت من JFBB متري

JDB محمل التشعبات الصلبة جلبة محمل شفة الجرافيت ذاتية التشحيم والخالية من الزيت من JFBB متري -

JDB محمل التشعبات الصلبة دليل القاذف jegb/jegbk

JDB محمل التشعبات الصلبة دليل القاذف jegb/jegbk -

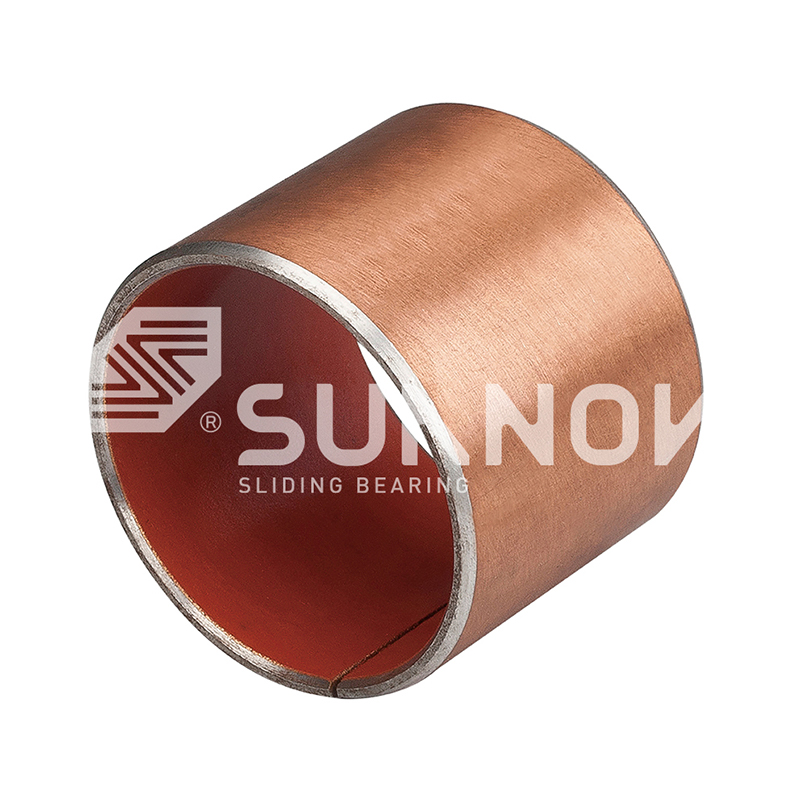

تحمل المعادن يحتفظ بالزيت 200#B محاكمة ثنائية المعدن (دعم الصلب+النحاس المصنوع من التشحيم الصلب مشتت)

تحمل المعادن يحتفظ بالزيت 200#B محاكمة ثنائية المعدن (دعم الصلب+النحاس المصنوع من التشحيم الصلب مشتت) -

-

-

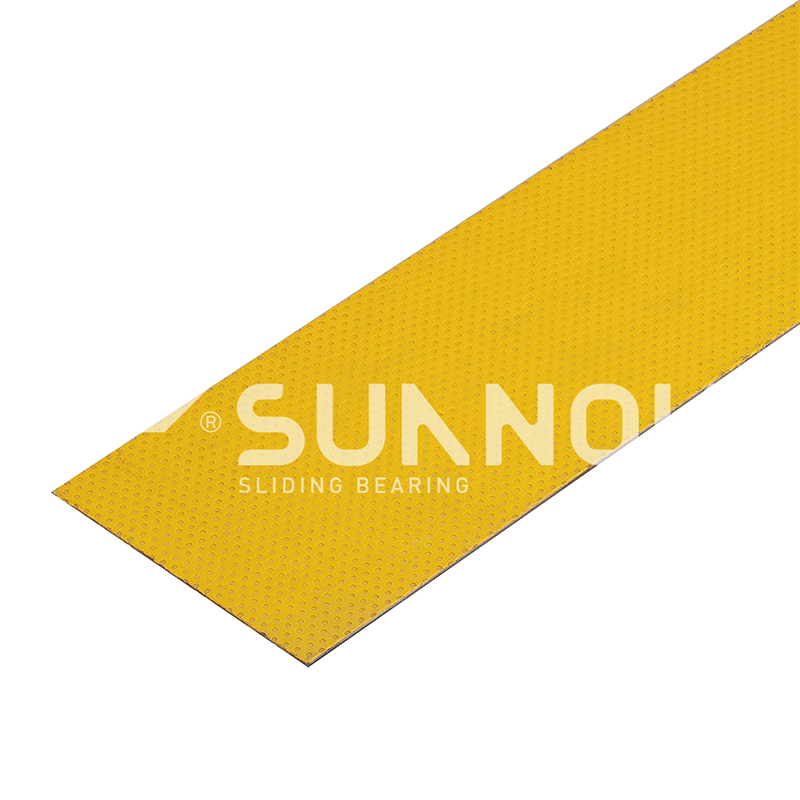

محمل تشحيم الحدود SF-2 SF-2SP القياسي القياسي القياسي للتشحيم الذاتي تزييت الشريط مع PTFE

محمل تشحيم الحدود SF-2 SF-2SP القياسي القياسي القياسي للتشحيم الذاتي تزييت الشريط مع PTFE -

FB090 برونزية ملفوف FB091 محمل ملفوف النحاس

FB090 برونزية ملفوف FB091 محمل ملفوف النحاس -

FB090 برونزية ملفوف FB094 البرونز ملفوف مع الأختام

FB090 برونزية ملفوف FB094 البرونز ملفوف مع الأختام

المحمل البرونزي: الانصهار المثالي من الحرف اليدوية القديمة والصناعة الحديثة

أخبار الصناعة- 1. الأصل التاريخي الحامل البرونزي الصب

البرونز ، كواحدة من أوائل السبائك التي يتقنها البشر ، لها تاريخ يمكن تتبعه إلى الوراء آلاف السنين. In ancient times, bronze was not only used to make weapons and ritual vessels, but also showed extraordinary potential in the field of mechanical transmission. With the continuous advancement of casting technology, bronze bearings have gradually become an indispensable key component in various mechanical devices. إنهم يحملون وزناً ، وينقلون القوة ، ويشهدون قفزة الحضارة الإنسانية من أدوات بسيطة إلى آلات معقدة.

JDB-600 Casting Bronze Bearing

2. جوهر صب البرونز

اختيار المواد: يعتمد صب المحامل البرونزية في المقام الأول على اختيار المواد. يمكن لسبائك النحاس عالية الجودة أن تعطي محامل خصائص مادية وكيميائية ممتازة من خلال أبعاد دقيقة. In modern casting processes, a small amount of other elements, such as lead and zinc, are also added to further improve the wear resistance and corrosion resistance of bearings.

تصميم العفن: القالب هو روح الصب. يمكن أن يضمن تصميم العفن الدقيق دقة الأبعاد وجودة السطح للمحمل. باستخدام تقنية CAD/CAM ، يمكن للمصممين إنشاء هياكل قالب معقدة ومتطورة لتلبية الاحتياجات الخاصة المختلفة.

Melting and pouring: In a high-temperature furnace, the bronze raw material is melted into a liquid state and then injected into the mold through a precise pouring system. This process requires strict control of temperature, speed and pressure to ensure the uniformity and density of the internal structure of the bearing.

Post-processing: After casting, the bearings must undergo a series of post-processing processes, such as heat treatment, machining and surface treatment, to achieve the final dimensional accuracy and performance requirements.

3. تطبيق المحامل البرونزية في الصناعة الحديثة

Automotive industry: In key parts such as the engine and transmission of automobiles, bronze bearings ensure smooth and efficient power transmission with their excellent wear resistance and heat dissipation.

Aerospace: In extreme working environments, bronze bearings can withstand the test of high temperature, high pressure and high speed, providing solid protection for the safe flight of aircraft.

Precision machinery: In precision machinery such as CNC machine tools and robots, the high precision and low friction coefficient of bronze bearings make mechanical movement more precise and smooth.

Marine engineering: In marine environments, the corrosion resistance of bronze bearings makes them an ideal choice for equipment such as ships and offshore platforms.

4. آفاق مستقبلية لتلقي المحمل البرونزية

With the continuous advancement of science and technology and the rapid development of industry, bronze bearing casting technology is also facing new challenges and opportunities. On the one hand, the continuous emergence of new materials and new processes has provided the possibility for improving the performance and reducing the cost of bronze bearings; on the other hand, the requirements of environmental protection and sustainable development have also prompted the casting industry to transform towards a greener and more efficient direction. In the future, bronze bearing casting will pay more attention to technological innovation and intelligent development to meet the market's growing demand for high-quality and high-performance bearings.